In modern industrial applications, metal clad plates with excellent properties are widely used. These materials are made by combining two different metals. They can also be made by combining multiple metals. Metal composite plates can take full advantage of the advantages of each metal. These metal composite plates can be manufactured by various processes. Among them, explosive welding has become one of the most effective and unique technologies. It plays a vital role in industries such as aerospace, shipbuilding, and petrochemicals. In this article, Hongfang will take you to explore explosive welded composite plates. Explain what they are. How the process works. Types of explosive welding. And why this method is often chosen for metal cladding applications. Of course, if you would like to know more, please contact us.

1. What are Explosive Welded Clad Plates?

First let’s understand what explosion welding is? Explosion welding (also known as shock wave welding or explosion bonding) is a solid-state welding process. It uses the energy released by the explosion to bond two metal plates together. Unlike traditional welding methods that require melting metal, explosion bonded does not melt the plates. Because this method uses an explosion to generate a high-pressure shock wave, forcing the two metals to collide and bond. This process occurs within seconds and forms a strong metallurgical bond between the metals.

Metal materials commonly welded using this method include stainless steel, copper, aluminum, titanium, and nickel. These explosion-welded clad plate for pressure vessels Stainless steel are generally harder and more corrosion-resistant than the individual materials. And they have higher performance and lower cost.

2. Explosion Welding Metal Sheets by Different Methods of Operation

There are several different ways to make explosive metal plates. There are two main methods:

a. Welding clad plates by parallel explosion

This method is to place two metal plates in parallel. Then use the power of explosives to bond them evenly. The explosion welded clad plates made by this method are suitable for suppliers who need large standard-sized composite plates.

b. Welding composite plates by multi-layer explosion

This method is more complicated than the previous method. It is to repeat the parallel explosion welding process many times. Finally, the multi-layer composite plates are bonded together. The clad plates made in this way are very strong. This explosion welding clad plates can be used in special industries. For example: pressure vessels, shipbuilding, etc.

In short, the explosive clad plates made by these two processing methods are very strong. Able to withstand extreme conditions. And suitable for different industries.

3. Why choose metal plates processed with the explosive bonding process?

Sometimes, traditional welding technology will destroy the characteristics of the plate. Because traditional welding technology will melt the plate at high temperature. Explosive welding does not have such disadvantages. Therefore, welding with explosives technology has become a viable solution. Explosive welded composite plates have the following advantages:

a. Strength and durability

The two metal plates are combined together because of the power of the explosion. You can imagine how firmly they are combined. Explosion bonding composite plates are very durable. They are also wear-resistant, corrosion-resistant, and high-temperature-resistant. They are very suitable for use in harsh environments.

b. Integrity

We all know that the traditional welding method is to melt and connect the plates at high temperatures. This method will change the structure of the plates. Ultimately, it will lead to poor use effects. Explosive welding uses physical methods to force the combination of two metal plates. Therefore, the explosion-bonded clad plates are very complete. Their characteristics are also fully preserved.

c. High efficiency

Do you know how long the welding with explosives process takes? That’s right, only a few milliseconds. During this process, the shock wave caused by the explosion causes the metal to collide at high speed and combine instantly. Such speed can greatly save time and improve efficiency. It is a very favorable performance in various application industries.

d. No impurities

Explosion-bonded cladding plates have another advantage that you may not expect. That is, its weld is very clean and pollution-free. Because any contaminants can be driven out during the high-speed impact process. Therefore, the cost-effectiveness of explosive welding of metal plates is very high.

4. Disadvantages of Explosion Welded Metal Plates

While explosion welded metal plates offer many advantages, they are not without their challenges:

a. Complexity and Specialization

Explosion bonded clad plate suppliers require expertise and skills. The process involves carefully controlled explosions. They must be performed precisely to ensure safety and effectiveness. Therefore, only professionals can manufacture explosion welded metal plates.

b. Regulatory and Safety Issues

Because explosives are used in the manufacturing process of explosive welding clad plates. Therefore, the manufacture of explosion welded metal clad plates requires specific safety protocols and regulatory approvals. This ensures the safety of workers and surrounding areas.

5. Hongfang’s Explosion Welded Composite Plates

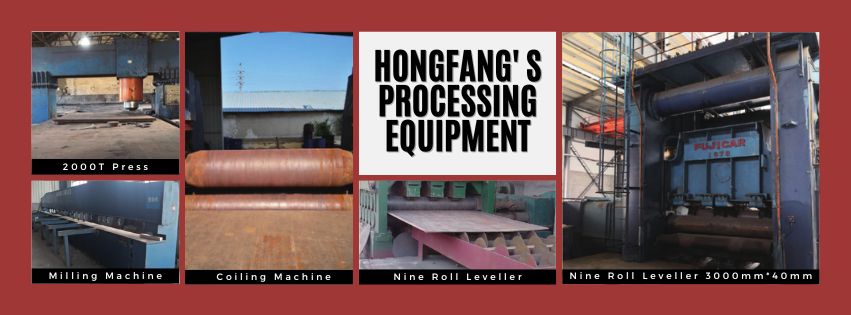

Hongfang specializes in advanced welding with explosives technology. We have state-of-the-art equipment and an experienced team. We are able to produce a variety of explosion welded metal composite plates, including stainless steel composite plates, copper aluminum composite plates, and nickel steel composite plates. These plates are used in industries such as petrochemicals, shipbuilding, nuclear power, and aerospace. These industries are critical for high performance and durability.

Hongfang takes pride in the quality of its products. Each plate is rigorously inspected and tested to ensure compliance with international standards. Hongfang’s explosion welded metal plates are high in strength, corrosion resistant, and have a long service life while maintaining a competitive production cost.

If you are looking for high-performance explosion welded clad plate for pressure vessels Stainless steel, please contact us. Hongfang’s team is ready to provide you with customized solutions. Whether it is a standard application or a more complex and specialized industry, Hongfang will meet your specific needs.