Product Features

Lightweight and High-Strength: The density of aluminum is much lower than that of copper, making the copper-aluminum clad plate lighter than pure copper plates. At the same time, the combination of aluminum and copper layers ensures overall strength.

Corrosion Resistance: Aluminum easily forms a dense oxide film on its surface, which effectively prevents further corrosion, giving the copper-aluminum clad plate excellent corrosion resistance.

Wear Resistance: The hardness of copper is higher than that of aluminum, making the copper-aluminum clad plate perform well in wear resistance.

Good Conductivity: Copper is an excellent conductor, and aluminum also has certain conductivity. Therefore, the copper-aluminum clad plate exhibits excellent electrical conductivity.

Excellent Processability: The copper-aluminum clad plate is easy to cut, weld, punch, and undergo other processing, facilitating the production of products in various shapes and sizes.

Production Processes

Hot Rolling Method: Primarily used for rolling copper-aluminum clad thick plates.

Cold Rolling Method: Primarily used for rolling copper-aluminum clad thin plates.

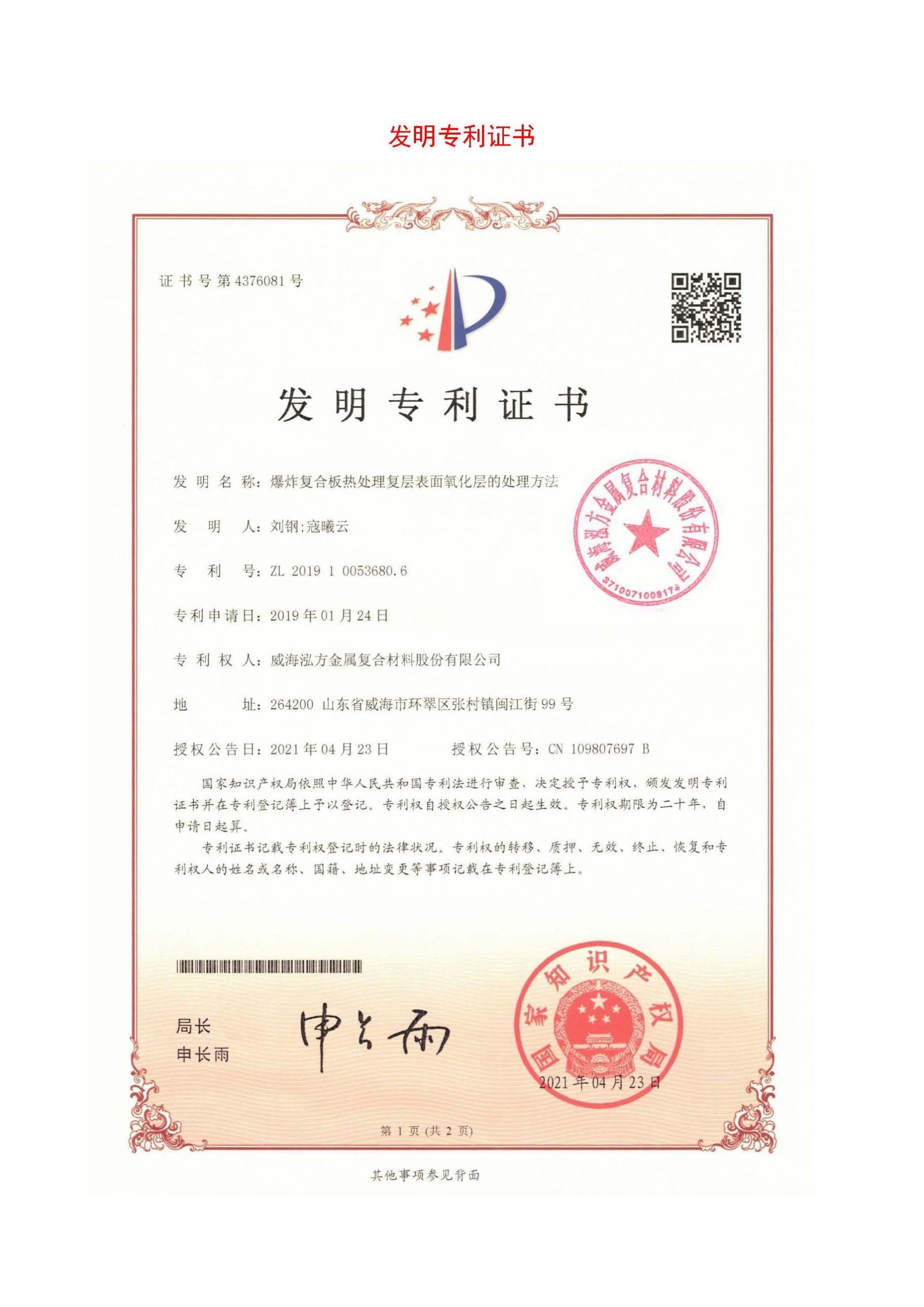

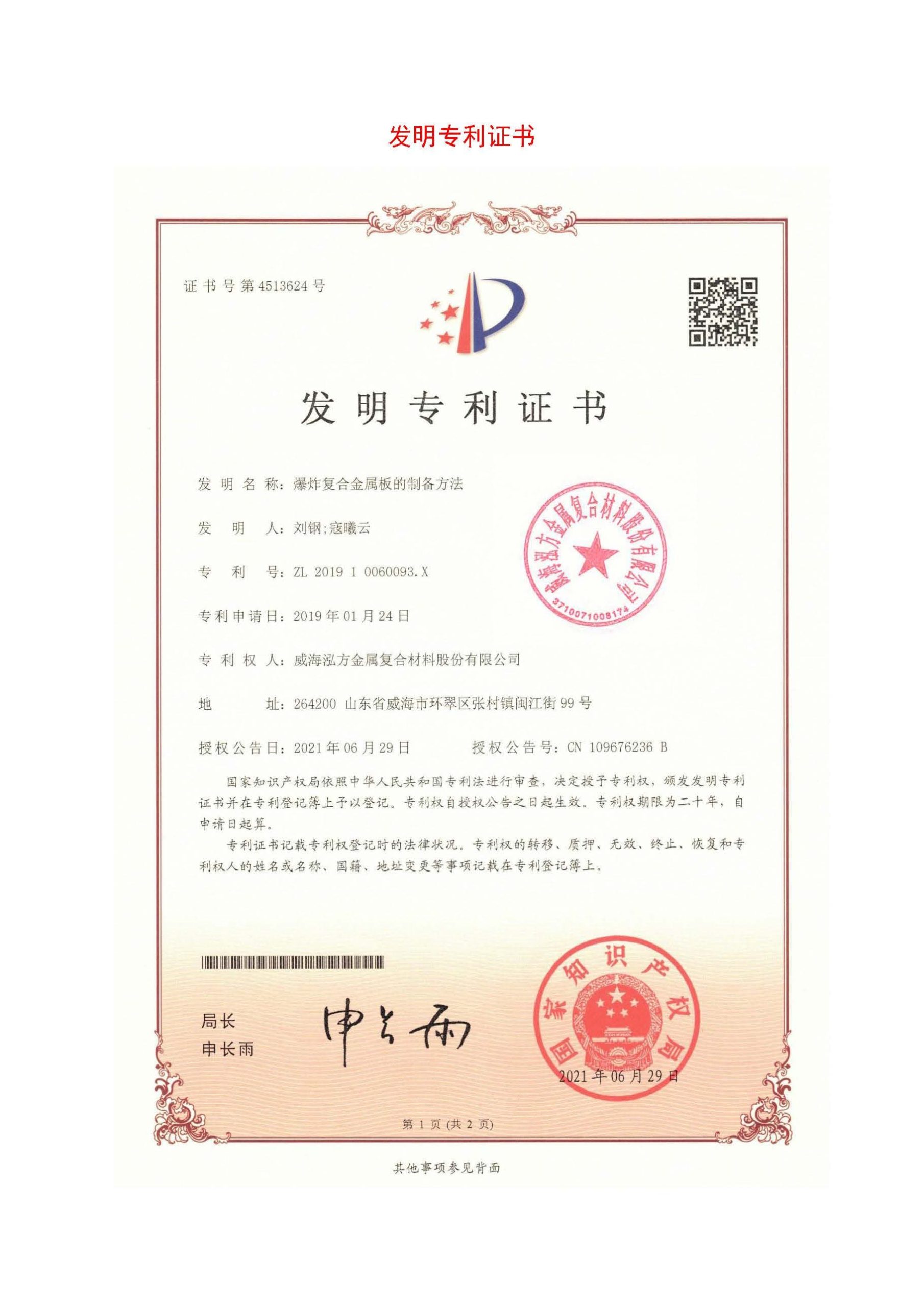

Explosive Bonding Method: The bonding process is very fast, completed instantaneously, with high bonding strength. It is mainly used for producing copper-aluminum clad thick plates.

Explosive Rolling Method: First, a rolling blank is produced through the explosive bonding method, and then it is rolled to obtain a copper-aluminum clad thin plate.

Product Specifications

The specifications of copper-aluminum clad plates are customized according to customer needs. The following are some common specification ranges:

Thickness: Typically between 0.4mm and several tens of millimeters, with specific thicknesses customizable based on customer requirements.

Width and Length: Customized according to customer needs, with maximum widths and lengths reaching several meters.

Application Fields

Due to its unique properties, copper-aluminum clad plate is widely used in multiple fields:

Aerospace: Used in manufacturing aircraft skin plates, skin frameworks, support structures, and other components to reduce weight and increase strength.

Rail Transit: Used in non-load-bearing exterior parts of subway cars, high-speed rail cars, etc., to improve operating speeds and reduce energy consumption.

Electronics: Used in manufacturing high-speed printed circuit boards (PCBs), heat sinks, electronic components, antennas, etc., to improve signal transmission speeds and performance.

Building: Used as wall materials, roofing materials, or visual curtain wall materials, effectively providing fire resistance, wind resistance, thermal insulation, sound insulation, and aesthetic appeal.

Chemical Industry: Used in storage tanks, conductive plates, vacuum equipment, etc., leveraging the corrosion resistance and conductivity of copper-aluminum clad plates.

Shipbuilding: Used in hulls, bulkheads, ship partitions, etc., to improve ship strength and corrosion resistance.