Stainless steel composite panels are a major technological advancement. It is a high-performance material widely used in industries such as petrochemical, shipbuilding and energy. Especially in the oil and natural gas pipeline industry, most of the cladding of stainless steel composite panels uses carbon steel. It can be said that it combines the strength and durability of carbon steel with the corrosion resistance and beauty of stainless steel. Has significant advantages in various applications.

In this article, Hongfang Metal will take you to discuss the manufacturing process, key considerations, technical parameters and applications of composite panels of stainless steel.

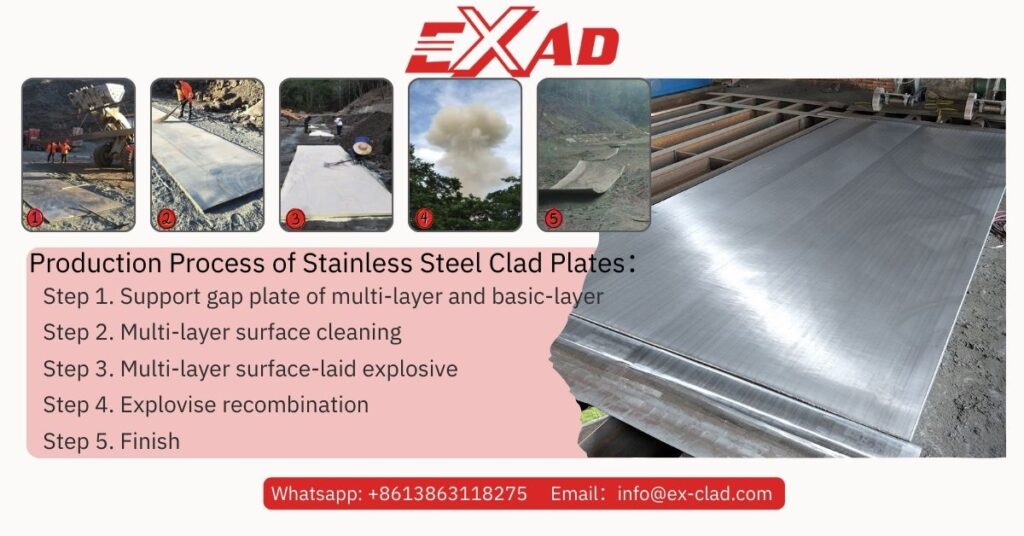

Production Process of Stainless Steel Clad Plates

Nowadays, our production technology of Stainless steel plastic composite plate is becoming more and more sophisticated. Different production technologies have corresponding application requirements. Among them, the most well-known processes are explosive bonding, hot roll bonding, cold roll bonding, welding, and more.

Explosive Bonding Process

Welding with explosive is a process that requires high operation requirements. The process mainly involves placing a layer of stainless steel on top of the carbon steel plate and separating them at a precise distance. Then a layer of explosive material is applied on top of the stainless steel. When detonated, the explosive force pushes the stainless steel layer onto the carbon steel sheet at high speed, forming a strong metallurgical bond.

The shear strength of this method can reach more than 400MPA. It is possible to create stainless steel plates that are up to 200 mm thick overall.

Explosive Bonding Benefits

Higher bonding of plates: The huge energy generated by explosion welding can make two different plates tightly bonded. We mentioned earlier that the shear strength of explosive bonding can reach 220mpa. Under such huge pressure. The stainless steel and carbon steel sheets layers can be highly fused.

High flexibility:The explosion bonding process can connect two different plates. Not only can it connect stainless steel and carbon steel. It can also connect stainless steel layers and materials such as copper and aluminum. Such a free combination can meet the needs of many projects.

No high temperature required:Unlike traditional welding methods, explosion welding does not require high-temperature melting of the plate. Therefore, this process can avoid deformation of the plate. It can also avoid the loss of mechanical properties of the plate.

Precise bonding:This process can process large equipment such as pressure vessels. And it can make the plates evenly bonded. Greatly improve accuracy and efficiency.

For almost a decade, Hongfang has concentrated on the method of explosive welded. We have professional equipment and a professional staff. All of these guarantee that our output satisfies the requirements.

Alternative Production Techniques

Rolling hot:Clean carbon steel and durable stainless steel plates are stacked together and heated to a predetermined temperature in a process known as hot rolling. After that, they undergo a high-pressure roll. The material’s microstructure varies with temperature during the hot rolling process. High-strength stainless steel composite plates may result from this.

Rolling cold:Another popular processing technique is cold rolling. This technology applies intense pressure mostly using hydraulic presses. One benefit is that there is no need to heat the bonding substance. The material’s microstructure won’t alter significantly in this way.

Welding:Small pieces are frequently joined using this manufacturing procedure. The material is heated locally until it melts and the pieces are joined. Welding provides superior corrosion resistance while being a slower procedure.

In conclusion, every approach offers special benefits of its own. Depending on the particular needs of the application, we can select one. Explosion welding is still the most adaptable and efficient technique for large-scale manufacturing, nonetheless. Please get in touch with us if you’re interested in explosion-welded stainless steel clad plates.

Precautions for manufacturing stainless steel composite panels

We now fully understand several manufacturing processes of stainless steel structural plates. Next, Hongfang will take you to understand the precautions when exploding and bonding stainless steel composite panels with long life:

Precautions

Before the step of exploding welding, we first need to ensure that the stainless steel and carbon steel are aligned. This is to prevent the plates from being misaligned and affecting the quality of the composite plate.

In addition, it is strictly forbidden to note that the plates used for exploding welding have not been welded with steel bars or other cladding.

In the process

During the process of exploding welding, ensure the safety of the site. And it should be carried out without affecting the surrounding environment. Do you know? All employees who participate in exploding welding must have professional qualification certificates. Hongfang uses professional teams. Therefore, you can use our products with confidence.

Post-inspection

After exploding welding, the integrity of the plate should be checked. Check whether there are cracks, pores, etc. on the surface of the multiple stainless steel sheet. Hongfang also has various professional testing equipment. We ensure that each plate meets international standards.

Applications of Stainless Steel Clad Plates

316 stainless steel composite panels can be used in many industries. Especially 10~200mm stainless steel composite panels made by explosion-bonded process. The following are some common application industries:

Petrochemical industry

When manufacturing pressure vessels. The most commonly used raw material is 304 stainless steel composite panels. Stainless steel and carbon steel are connected by explosion bonded to manufacture storage tanks, pipelines and other similar equipment.

Marine industry

Ship parts such as decks that are common in our daily lives can be made of stainless steel Sandwich Panels. And the explosive bonding process can ensure the strength, bonding, corrosion resistance, etc. of the plate.

Power industry

In the field of power generation, many projects require professional equipment such as heat exchangers and boilers. And these equipment can also be made of stainless steel mental composite panels. This can resist high temperatures and corrosive environments.

In addition, the most popular stainless steel plate can also be used in defense, medical, equipment manufacturing and other industries.

Hongfang Jingtong manufactures Mirror finish stainless steel composite plate using explosive bonding technology. The base material of our stainless steel compositeding is Q235B, Q345B and other specifications. The stainless steel layer is 304, 316l or duplex stainless steel. The maximum width of our stainless steel composite plate materials is 2500mm and the maximum length is 13000mm.

Whether you want to manufacture pressure vessels, heat exchangers or storage tanks. Our high-quality materials can meet your needs. Of course. If you don’t know what kind of plate is suitable for your project, you can also ask us for direct recommendation. We provide professional services. Contact us to get a quote now.